Jewelry Making Tools Uses and Tips...

Friday, November 27, 2015

Saturday, October 31, 2015

Making a Byzantine Chain

Byzantine Chain

Materials:

- Wire 4'. 6" ~ 132cm 20 gauge 2.5mm ID (Inner Diameter)

24 rings per 2cm (204 rings) - Wire 3' 9" ~ 114cm 18 gauge 4.0mm ID (Inner Diameter)

14 rings per 2cm (120 rings) - Clasp

Tools

Chain nose pliers

Flat nose pliers or Bent nose pliers

Wire tie, or any lace

Jewelers saw, or Flush cutters

Instructions:

|

| Linked Rings 2-2-2 Chain |

|

| Flipping the silver rings to the chain sides |

- Open widely the jump rings to be easy to link them

- Place a wire tie or a lace through two closed rings and twist the ends of the closed wire

- Link an open ring through the two closed rings and close the ring. Link a second ring through the same path and close the ring

- Link 2 more open rings to the chain and close them forming a 2-2-2 chain

- Grasp the chain, and the wire tie in your non dominant hand and flip the two top rings (silver rings) to the sides of the chain facing down

- Lift your fingertips away and pin the (silver rings) with your thumb and turn them to the outside of the chain, and push the flipped rings (silver rings) up a little to position against the sides

- Split the two top rings and insert and open ring between the top two rings and through both rings (silver rings) beneath them, then close the ring

- Insert another open ring to the the same path beneath them (silver rings) and close the ring

Splitting the two top rings

| ||||||

| Inserting a Ring-beneath the silver rings to lock the pattern Locking the pattern |

| |||||||||||||||||||||||||||||||||||||||||

| Byzantine Chain Maille pattern |

|

| Repeating pattern to form 2-2-2 chain again |

|

| Byzantine Chain Maille |

Wednesday, September 30, 2015

How to make Celtic knots links and eye pins loops

Celtic Knot Links

Celtic knot links are interlocking coils of wire held together with simple eye pin links. Using Bail forming pliers helps to make each link the same size and shape.

Materials:

- Round dead soft wire in 18 gauge - 1.02 mm (about 5' ~ 152cm)

Tools:

- Ruler, or Tape measure

- Steel wool

Jewelry pliers:

- Round nose pliers

- Chain nose pliers

- Flat nose pliers

- Bail forming pliers

- Flush cutters

- Clean your wire with a super fine steel wool.

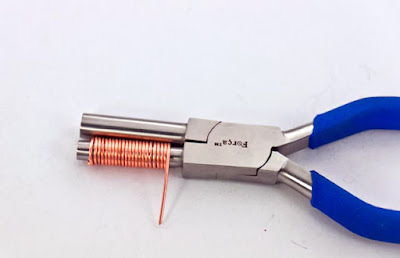

Bail Making Pliers - Place one end of the 18 gauge wire in the jaws of large Bail forming pliers and begin to form a coil on the smaller jaw. As you turn the pliers over your right hand bring the long end of the wire, and continue coiling.

- Wrap the wire around the jaws without gaps between the coils

- When you complete the coiling around the jaws, press down the last 6 mm, using the Flat nose pliers.

- Clean your wire with a super fine steel wool.

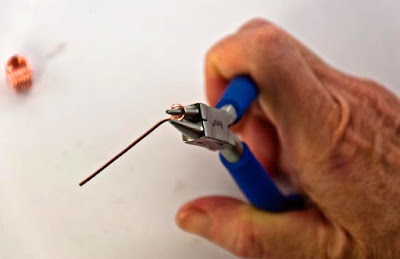

Insert Chain nose pliers into the coil, and count six rings. at this point grasp the coil, and tilt the pliers back separating part of the coil.

Flush cut the coil

Flush diagonal side cutter with Tungsten Carbide blades

Pick two short coils, and insert one of the rings of one coil into the center of the other coil.

Use a Chain nose pliers, or your fingers to turn the coil around like a key ring until the coils are interconnected.

Flush cut 2"~ 5cm of a 18 gauge wire.

Form a small eye pin loop using the Round nose pliers.

Break the neck of the eye pin using the Chain nose pliers.

Insert the eye pin loop into the round nose pliers jaws and center the loop on the straight wire.

Insert the eye pin into the interlocking coils, and create a second eye pin loop.

The Celtic knot link can be used on a bracelet, or necklaces to enhance your jewelry design.

Monday, August 31, 2015

Which pliers should I use for Chain Maille jewelry?

Bail making pliers

|

| Bail Making Pliers |

Making wire coils of small or big inner diameters for jump rings for Chain Maille jewelry are very easy to form by wrapping wire around the jaws. These pliers are composed of two long cylindrical jaws

with

different diameters on each jaw of the pliers which allow you to form

Jump Rings coils of 25 mm to 38 mm length in multiple sizes.

These bail making pliers has jaws sizes:

1.50 mm & 2.50 mm

- 4.00 mm & 6.00 mm

7.00 mm & 9.00 mm

Opening and closing jump rings

Is one of the most basic and common techniques used in Chain Maille making.- Flat nose pliers are used for thicker wire ( e.g. gauge 16 - 1. 32 mm, or gauge 14 - 1. 63 mm).

- Chain nose pliers are used for thinner wire (e.g. gauge 21 - 0.71 mm, or gauge 22 - 0.64 mm).

**Note: always pull the rings towards your body to open them, never pull them apart from side to side because they will get out of round shape, and to close them in the opposite way you will hear a clicking sound when you reach the ring ends.

|

| Opening Jump Rings |

Wednesday, July 29, 2015

Unveiling Endless Uses of Flat Nose Pliers in Jewelry Making

Endless Uses of Flat Nose Pliers in Jewelry Making

While Flat Duck Billed nose is the opposite and the exception to tapered jaws, Flat nose pliers, Snipe nose pliers, Needle nose pliers, Bent nose pliers and Chain nose pliers all taper towards a flat end. We can resume saying that the uses of Flat nose pliers in jewelry making is endless.Flat Nose Pliers Jaws Types:

|

| Parallel Flat Nose Pliers Serrated Jaws |

- Smooth surface in the inner jaws

- Serrated surface in the inner jaws

- Brass Lined inserts in the inner jaws

- Nylon Tips inserts in the inner jaws

Flat Nose Pliers Uses:

|

| Spiral Post Earrings |

- Holding or Filing wire and sheet metal

- Opening and Closing Jump Rings for Chain Maille making.

- Straightening wire with Parallel Flat nose pliers with Nylon jaws to prevent dents or marring.

- Twisting wire with Parallel Flat nose pliers Serrated jaws with a "V" slot for better grip

- Bending angles or Flattening crimps.

- Flattening wide bands for Rings and for Closing gaps on joints for Soldering operations often Parallel Action Flat nose pliers are used because the pressure is even along the jaws.

- For Gripping or forming spirals shapes on round soft wire and avoid denting or flattening the wire it is better to use Flat nose pliers with Nylon jaws.

- Holding Round Beads or Calottes also known as Clamshell Crimps, Bead Tips or Necklace Ends; these findings are used to get a perfect nice looking finish to your jewelry creations.

- While

keeping your Jewelry work away from scratches, kinks, dents or slipping

is a continuous challenge to any jeweler everyday, they can be

prevented using Flat nose pliers which have treated jaws or matte surface in the inner jaws to avoid slipping or scratches on the wire or metal surfaces or by using pliers with Brass lined jaws or with Nylon jaws for an extra protection.

I would love to hear from you with any other suggestions and uses for all these types of pliers. I welcome your feedback

Thursday, April 23, 2015

How to set Stones with Gem Setting Pliers

With these Gem setting pliers setting stones are easier that you think. The concept is very simple; the

lower jaws of these pliers are stationary while the pliers handle allows the upper

jaws to move up and down, but only up to the distance you already set with the wheel, avoiding fracturing the stone with excessive pressure.

|

| Gem Setting Pliers |

This particular model features brass lined jaws which means no marring or

scratching your prongs while you are setting the stone in your jewelry.

|

| Gem Setting Pliers with Brass Lined Jaws |

Thursday, February 19, 2015

How to make holes on Metals for Jewelry Making

To make holes on metals for Cold Connections, Rivets, Links or for Piercing or Sawing Techniques

The techniques which are used to make holes in Jewelry Making are Drilling or by Punch with Cutting Dies.

There are diverse types of tools to use according to the size of the hole that you want to make in your sheet metal piece.

If you need holes with a diameter less than 1.5mm or large sizes you have to use a variety of tools as follows:

A metal ruler or a plastic one. I found one ruler in particular in a fellow blog about scrapping that caught my eye because you can mark precise and even equidistant holes around a disc shape. This is a time saving tool for jewelry making that will help with your designs.

| Piercing Ruler |

|

| Bench Block and Chasing Hammers |

A Chasing hammer to be able to strike over

the marking punch with the hammer to make a small dent on the sheet metal so the HSS Drill bits don't slip over the metal stock surface.

A Bench block or an anvil as a hard surface to receive the strike of the punch over the metal without deforming the back of the sheet metal surface.

Or an Automatic Marking Metal Punch. These ones come with a spring mechanism which regulates the strike on the punch to make light or hard indentations on the metal surface.

HSS (Stands for High Speed Steel) Twisted Drill Bits and a wax lubricant to smooth and cool the drill bits during the drilling process.

Then we could use a Flex Shaft Rotating Tool or a Jewelers Manual Drill Eggbeater style to attach the drill bit whichever size of choice and start drilling the piece of sheet metal over a wood surface.

|

| Jewelers Hand Drill Eggbeater Style |

|

| HSS Drill Bits 1.0mm ~ 2mm Set |

| Parallel Punch Metal Hole Pliers |

If you need standard 1.5mm holes that fit almost all wire sizes, another easy way to do it is using Parallel Metal Hole Punch Pliers.These parallel pliers cut clean holes over the sheet metal up to gauge 20 or 0.80mm thickness and have replaceable cutting pins which last a long time and are quite easy to change.

To make holes of 3mm to 16mm of diameter you can use a Jewelers Disc Cutter Punch Set. This tool is very practical since is equipped with 14 different punch sizes to allow you to cut precise holes and disc metal blanks to use for jewelry making, earrings, bracelets, necklaces, pendants or chains.

|

Jewelry Hardened Carbon Steel Disc Cutter Metal Set of 14 Pieces 3mm - 16mm. |

Subscribe to:

Comments (Atom)